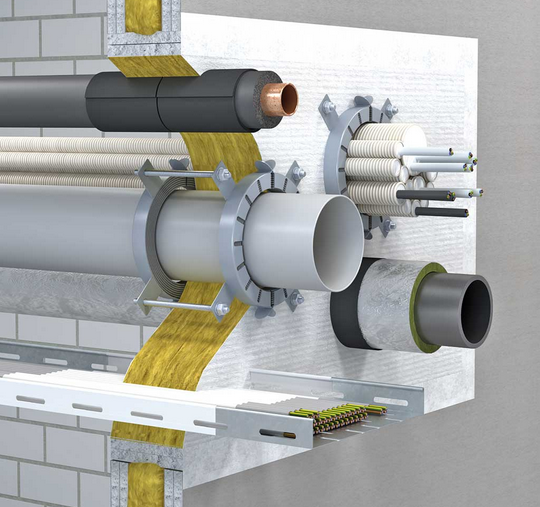

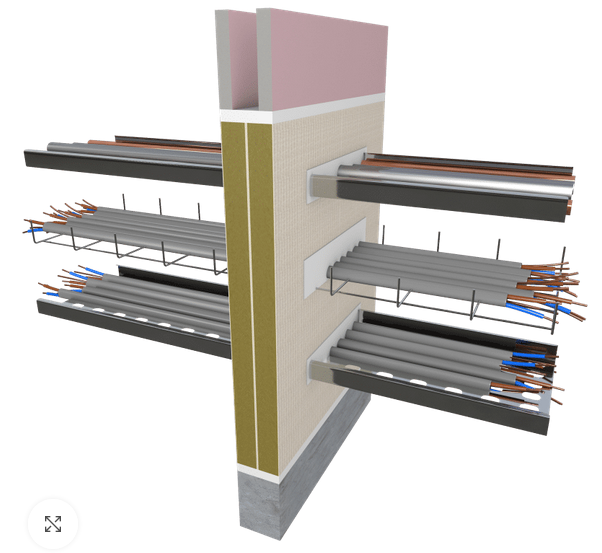

Openings in walls and ceilings constitute a major threat to the spread of fire to adjacent spaces. According to the Royal Decree of 7 July 1994 laying down basic fire prevention standards, penetrations through walls of liquid or electrical conduits must not adversely affect the required fire resistance of the building elements. The fire-resistant sealing of such penetrations must therefore meet these requirements, using the appropriate seals for the different types of ducts. The sealing of this penetrations is therefore professionally carried out by our specialists. After completion of the work, the work is also sealed by applying a sticker.

UNDER NO CIRCUMSTANCES should the duct be sealed with fire-resistant PU foam. This is a common problem where many people think to quickly seal the duct with fire-resistant PU foam but that is INCORRECT. The fire-resistant PU foam will be gone in no time in case of fire.

INCORRECT

INCORRECT INCORRECT

INCORRECT INCORRECT

INCORRECTSealing penetrations correctly is complex because the different types of penetrations or pipes require a different sealing technique, so this can only be carried out by specialists.

It is a must to pay sufficient attention to the penetrations to avoid the following problems:

It is desirable to make an inventory of the penetrations, if necessary, with photographs in the post-intervention file. It is then possible to check afterwards whether changes have occurred in relation to the initial situation.

If you have any questions, please click here to request more information or for a non-binding consultation!